Austin was hit by a massive ice storm in early February. We lost power on Wednesday morning and didn’t get it back until Saturday. We live out of town on the edge of the barrio, so it’s not surprising others were prioritized before us. I know several friends who had to do five and six days without!

One big problem on The Farm where I live is that, since we’re on a well with a 240V pump, we lose water when we lose power. Combine that with the cold weather, and that means you can’t drip your pipes to protect them. This time we didn’t have too much damage as the really hard freeze only happened for one full day. I also had finished putting a new skirt on Danielle’s trailer, which really helps protect the pipes.

We’re all Burners or at least experienced campers, so we’re better equipped than most to handle this kind of situation. In the yurt, after finally admitting I couldn’t sleep through the power loss, I went and got my Olympic Wave 6 gas heater and scrounged up a propane bottle. This thing will keep the yurt at 60 o F+ for at least a week on the Low setting on one 5 gallon propane bottle. My water heater had already been broken before the storm, so dishes were already piled up in the sink. I also generally cook on an induction cooktop or my air fryer, so I switched over to whatever I could eat easily, which, in my world, isn’t much. I really like to cook, but also have very bad portion control for easy snacks, so most of the food I have requires cooking to be edible. Pretty soon I was out of fruit and easy veggies, and I also didn’t want to open the fridge very often.

Our friend Thomas, who often volunteers with Austin Street Medics and other volunteer orgs, had a generator up in running after a day or two to keep our four large chest freezers from going bad. The whole experience was dark and depressing, especially because I have really bad seasonal affective disorder that I usually fight with lots of indoor LED lighting. In fact, I have a completely different Yurt Light Dome project I’ve been working on for months to help with that problem. More on that in another post.

The Wins:

Half of my tiny fridge capacity is in my van, which has minimal solar power and a 12V fridge with a Danfoss compressor. Even in the middle of winter, the 400 watts of solar is enough to keep things cold. The fact that the fridge doesn’t have to work as hard in the cold weather helps. This means I had a place to move some items if needed.

Thomas kept our deep freezes running, so we had a place to move freezer stuff. This was complements of a dual-fuel generator running on propane. This is an example of real resiliency, as he has *two* generators and neither one was initially working due to bad fuel. However, propane doesn’t need a carb, so by switching that second generator over he was able to get it working. He also has a large rolling battery for exactly these situations so he could charge that, then rotate it between the freezers. Huge props to Thomas for keeping all that shit running in the middle of a crisis!

The yurt stayed warm. Thanks to the used fiberglass insulation I installed last summer and weatherproofing improvements, the Wave 6 heater was able to keep things in the 60s without even running all the time. It’s a bit of a chore to light, you have to hold the button down for 30 seconds for the thermocouple to stay on, but it provides safe, efficient heat with no electrical power. Thomas also shared a small Buddy space heater with Danielle so she could keep her bedroom warm.

Danielle had propane heating and a gas stove on a big tank, so she was able to cook and heat throughout. While I was almost on the verge of installing one of the many camping cooktops I had in the yurt, it just made sense, especially with the cold, to cook at Danielle’s place instead.

Junior, my 2007 Dodge Sprinter off-grid stealth conversion, is able to act a generator in emergencies. There are a lot of problems with running the 3.0 diesel at idle, including clogging the diesel particle filter and possible engine damage, but it works. My house batteries are currently shit (see below), but they exist, and I have a 3000 watt true sine wave inverter, so I can provide enough power to run a 15A circuit when the engine is on. I ran then van for at least a few hours every day, and luckily had just topped up the tank. At $4.20 gallon, it’s a super inefficient and expensive way to create power, but it works in a pinch. The power from Junior was mostly used to charge phone power banks and keep the fridges from totally melting down, and to occasionally provide a few hours of pseudo-normalcy when things got really dark psychologically. Running the engine also charges the house batteries, which can then be used to run small things for short periods of time. If I needed to, I could also have run the heater to warm that space as an emergency shelter. Although there area lot of minor problems with Junior, and he’s frequently full of junk, he’s a very good resource to have for off-grid living, and that’s by design.

Friends, lovers, and helpers. Lots of people came through for us during out outage in the few places we needed help. Thanks to everyone who lent a hand, or offered!

The Problems:

Neither Danielle or I has any kind of fossil fuel generator. The fact that Thomas had his really helped, but considering the fact between us Danielle and I have two Sprinter camper conversions and frequently go to Burns and camping, it would really help if we had at least a 2000w unit for these kinds of emergencies. If we had had one, we could have probably run her trailer and my yurt most of our waking hours as long as we didn’t use any of the power for heating.

The house battery pack in the van is garbage. It consists of four very old 6V golf cart batteries that have been on their last legs for years and a spare car starter battery I inherited from my Mom. The voltage sags badly with any kind of non-trivial load, so the batteries can’t handle, say, a small heater or induction stove even though the rest of the system can. If I want to use heavier loads, I have to fire up the engine for the duration. I only have 400 watts of solar on the van, which is barely enough to stay ahead of the fridge in winter with the lower sunlight levels, but if I had a bigger battery, that extra power would add up and potentially last for days in exactly this kind of pinch. I don’t regret cheaping out on the batts initially, because I suspected I wouldn’t use the van as much as I wanted, and I was right. The system has worked for many years now, but I haven’t taken it on the road except to local Burn events for several years. However, this event and other like it last winter have convinced me it’s time to invest in a beefier battery setup, probably a self-built LiPo rig. I can’t afford that right now, but it definitely needs to go into the budget. If I’d had a system like that during the storm, I would have been able to have some form of continuous power throughout even if we didn’t have a small generator.

Being without water is worse than being without E-! The fact that our well pump won’t work without grid power is a huge failure in what’s otherwise a very resilient setup out here at The Farm. We already have plans to fix this, but it will take a while with all the other upgrade projects and limited funds. Now, I ran the water system in the yurt off of a 12V system for over five years that could make 5 gallons of water last for *two weeks* of dish and hand washing. Our well water isn’t potable, so we already bring our drinking water in from friend’s places and run it through a Berkey filter. Despite still having this setup, and the fact that I got it into the yurt on the last night of darkness, I never actually got it fully set up because it’s a little too hard right now. The biggest issue is providing power, as I used to run it off of a 12V converter from grid power, and I didn’t have any extra 12V batts lying around I could use.

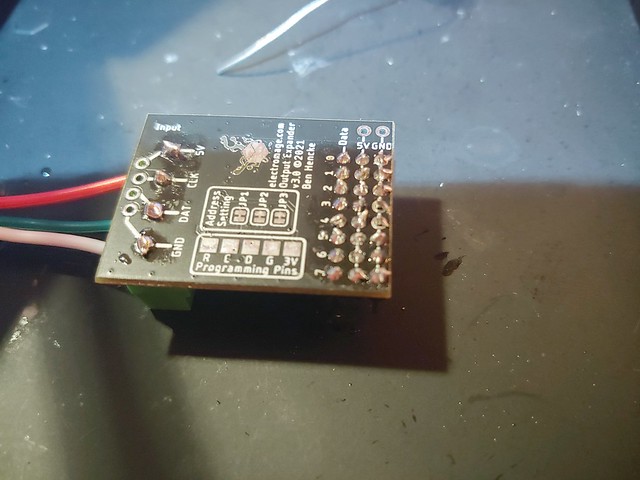

However, this brings us to a good generalized tool that would help with all of this. Both Thomas and I have extensive collections of 18V rechargeable tools. Mine are Ryobi, and his are Makita. Many things that run on 12V can actually use 18V unmodified, and for those things that need the actual 12V, it’s trivial to get chips that will downstep without much power loss. I have some solution to most of my power gear that can work on 12V, but I didn’t have enough capacity or number of batts for that to help much during this emergency. One great solution would be a way to patch a number of these batts together and/or make a way to plug them into stuff that uses 12V. One solution that I’ve used before is these simple 3D printed caps for Ryobi batteries. Combined with wire they provide an easy way to get that power somewhere else:

https://www.thingiverse.com/thing:1194867: Four Days Without Power or Water

I only have about four or five of the Ryobi batts, but Thomas has a lot more of the Makita ones, and making adapters is pretty easy. The ability to run everything small like lights, phones, maybe even computers off of those is very appealing, and would be easy to set up. That would justify buying, or even making, more of them. It wouldn’t let me weasel out of getting a bigger portable battery system of the yurt or van, but it’s a resource I didn’t really use during past emergencies, and it could solve a *lot* of problems. The larger house batts would provide a better aH/Electronic Expense ratio, but they would fill in a lot of gaps.

The Takeaway:

We were pretty well equipped to handle 4 days without power. Having propane backups really saved us, as did one big generator and house battery. The low hanging fruit of solutions to problems are

- A 2000-3000 watt generator

- At least one large house battery for the van/yurt that can run things for several days

- A way to keep some kind of running water happening both at a Farm-wide and at a per-building level with no grid power

- A modular system for combining and possible down-regulating 18V tool batteries to use to run 12V gear.

- Whatever small chances are needed to get my previous 12V water system portable and easy to set up, possibly even built into the yurt (there’s already one in the van, but it was too junked out to use) so that it’s trivial to switch over when needed.